Your search for title returned the following results.

Project title: ‘Source of the Nile Ltd’ – Semi-Intensive Tilapia Aquaculture in Earth Ponds

Partners/investors : Greenfields Uganda Ltd. and Lake Harvest Aquaculture Ltd. (Zimbabwe)

http://www.greenfieldsuganda.com/

Project budget: 850.000 euros

Subsidy: 510.000 euros

Start Project: september 2005

Current Status March 2009: The project runs succesfully and new investors will come in to expand the fish farm to double or triple its size.

See also the link on the website of the EVD:

Source of The Nile (S.O.N) Fish Farm Ltd. 2007

S.O.N started digging its first ponds october 2006. S.O.N staff decided to dig manually.

December 2006:

Tilapia nests Start Tilapia breeding programme

July 2007:

January 2008:

Happas

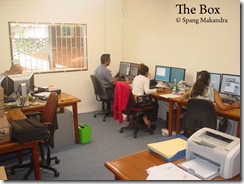

Office

2008

ponds and shadehouse

2008

This project was submitted in August 2007.

Project Budget: 825.000 Euros

Subsidy: 495.000 Euros

This project was approved by the EVD for funding in December 2007.

However, the Dutch partner/investor and the EVD could not agree on certain terms during the contract negotiations and therefore the Dutch partner withdrew from the project.

Uganda is still in great need for good quality Aquafeed as is East Africa as a whole. All high quality fish feeds are being imported which makes it highly expensive, less profitable and difficult to start or expand fish farming activities.

Without local production in any country in East Africa, Aquaculture will not take off or develop to a business which could easily export large amounts of high quality Tilapia into the region or Europe.

All existing fish farmers in East Africa would profit enormously if a foreign company would invest in the set up of an Aquafeed production plant. Needed is not only an investor but mainly foreign expertise and knowledge.

PSOM 2007

August

Aquafeed Uganda Limited

This project proposal was submitted in February 2009 and was approved in May 2009.

The partners have received a PSI contract/Beschikking.

The partnes have finalized the first Result: establishing a Joint Venture.

Project budget: 1,5 million Euros.

Subsidy (50%) 750.000 Euros.

Summary:

Through the proposed project, a joint venture will be formed between veterinary medicine

producer Alfasan of the Netherlands and distributor Farm Support of Uganda. The new company will be the first in Uganda to produce high quality generic medicines meeting GMP-Pharma standards, thus providing livestock owners and veterinary service providers and distributors in Uganda

and neighbouring countries with locally produced medicines.

The new company responds to a growing market for high quality animal products, in which only relatively expensive imported medicines, some of substandard quality (at low prices), are

available to professional animal health service providers and farmers. Access to good quality veterinary medicine at affordable prices will therefore contribute to improve livestock health and productivity. The effectiveness of the medicines will be tested and monitored, both in the field and through Alfasan’s in-house quality control laboratory in the Netherlands. Appropriate support

will be provided to agents, distributors and agricultural advisors to constantly improve the service level to farmers.

Once all staff has been trained (a process that takes at least one year), and the manufacturing

plant is certified and fully operational, the facility will be capable to produce up to

20% of Uganda’s demand for liquid and solid (powders) veterinary medicines.

Among the expected spin-offs are high level direct en indirect (resellers)

employment, the introduction of new technology, significant foreign exchange savings

through import substitution and exports, and potential follow-up investments in

other veterinary products, such as injectables and acaricides.

February 2011

Alfasan Uganda Ltd. has been established and building of the facility has commenced last month.

March 2016

The project was delayed but this month the building will be finalized and training staff can start.

2016

2012

October 2012. After some delays due to the rainy season amongst others, construction has re-started.

2013:

Patrizia Sterenberg – is a consultant who has specialized in the PSOM/PSI Programme (Private Sector Investment Programme, DGGF), of the Ministry of Foreign Affairs/Development Cooperation). She matches business partners, writes PSOM/PSI applications, intermediates between the project partners and the EVD/Agentschap NL, and manages the project results during the two-year duration of the Pilot Projects being implemented. Since the first year of her business set up, 2004, she has submitted several project proposals. See Projects for examples and currently operational projects.

She personally manages the PSOM/PSI projects for the project period of two/three years concerning all the RVO/Agentschap NL obligations the project partners need to fulfil being Result Reports, financial management and payment requests. She has experience in translating Agentschap NL/RVO policies, conditions and (tender) instructions into practical tools for entrepreneurs wishing to apply for funding.

The next LAST tender period has closed in March 2014. PSI has been reshaped into the DGGF fund (Since July 2014). Depending on the sector and country of your project and project idea other funds are available. I currently (2016) also represent several SME’s on the African Continent (Kenya, Sudan, Malawi, Uganda, Gabon, Ivory Coast, Rwanda, Tanzania) to assist them in obtaining Equity, Loans, or (part) Grants. This is across all sectors.

Contact me if you have any questions or requests.

PROJECTS :

Tilapia Aquaculture Uganda (2005) More photos Testimonial Website Lake Harvest

Plastic Recycling Uganda Industries Ltd. (PRI) More photos PRI (incl. 2011) BBC/CNN item on PRI

E-Media Develoment Studio in Surinam: Website Spang Makandra

Post Consumer Plastic Recycling in Tanzania

Recycling of Post Consumer Refrigerators in Yutian, China

Production of Aquafeed in Uganda

Piloting a Cardiology Clinic in Uganda, Africa Pictures Published articles

Pilot Production of Generic Veterinary Medicines in Uganda, Africa

Recycling and remanufacturing of Toners and Cartridges in Ethiopia, Africa

Manufacturing of polypropylene woven bags for the cement and agro industry in Zambia, Africa

Production and Export of specialty peanuts in cooperation with out-growers in Bolivia Website: Agritrade Website Oerpinda

Cultivation and export of Chili mash in cooperation with out-growers in Mozambique

In-Situ road recycling in South America, Suriname

Sudan: Hydraulic workshop and chrome plating facility; tender of August 2010

August 2011 projects: Malawi (PVC pipes), Armenia (Strawberries in greenhouse) and Uganda (MRI medical imaging). still ongoing

August 2012 projects: Sudan (Collection and Incineration of Medical/Hospital Waste) and Armenia (Leather Tannery). Still ongoing

August 2013 projects: 1) Production of Chocolate and Licor, Peru. 2) Filmstudio & film equipment rental, Paramaribo, Suriname (starting in 2015). Still ongoing until 2017.

March 2014 projects: production of peanuts in Sudan including farmers training and outgrowers and Production of RDF in Sudan and Production of several type of doors for naval and offshore industry, Vietnam. Still ongoing; fase 1 of the project, 4 more to go. These projects will continue until at least 2017.

More news to follow soon. In the meantime check this out: http://www.bbc.co.uk/news/business-12581674. This is the former PSOM project (PRI Uganda) which has been sold to SAB Miller in 2010. It is still running and successful.

This project was already underway when Envirotec BV asked me to take over the project management due to problems between the partners. The project was at a stand still at the time.

After mediation the project re-started and was finalized in 2008.

The company named Enviropet Tanzania Ltd. is still operational.

Installing the machines at Dar es Salaam:

Training staff by Mr. Driessen Almost ready…..

This project was submitted in February 2007 and was approved by the EVD for funding.

Unfortunately, the Dutch partner decided to pull out just before the contract negotiations with the EVD.

The Board of the Dutch company reconsidered their focus of investments in several countries of which China was one.

So although this project was approved it will unfortunately not be implemented.

Project budget: 1,5 million Euros.

Subsidy amount: 750.000 Euros

500.000 euros of additional investment was planned by the Chinese partner in a CFC burning/cracking installation.

Project title: Recycling of post consumer refrigerators in Yutian County, China (RPCR)

Abstract from the project proposal:

Environment, recycling and legislation

China’s gradual transition to a market economy during the last two decades has put China among the world’s fastest growing economies. While economic growth has increased incomes and improved health indicators, as well as reduced overall poverty levels, growth has not been totally benign. Environmental pollution is damaging human health, air and water quality, agriculture and ultimately economy. After 20 years of uncontrolled economic development, officials and citizens alike are finding it hard to ignore the chronic environmental damage. The government of China signed the Kyoto protocol in 1998, and although not bound by its emissions restraints, the Chinese government announced extensive protective environmental measures and has developed new legislation on collection, recycling and disposal of electrical and electronic waste (WEEE). China has shaped its China WEEE and RoHS [1](Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) after their EU counterparts. However, China’s attempts to regulate the industry and establish a financially viable and safe WEEE management system are facing significant challenges. The existence of an extensive informal sector, combined with a lack of environmental awareness among WEEE collectors, recyclers and consumers, are contributing to China’s difficulties in developing a financially and environmentally sound recycling and disposal system.[2] The importance has been widely recognised but progress is slow. Without any alternatives for informal recycling processes it is very difficult to establish a regulated e-waste management framework[3].

Electronic and Electrical (e-) waste

One of many environmental problems is the disposal of waste in general and e-waste in particular. China has emerged as both major manufacturer and as consumer of electronic and electrical products. Last year (2006), manufacturers sold (on the Chinese market) more than 80 million mobile phones, 40 million TV sets, 43 million air conditioners, 19 million refrigerators and 16 million computers. China now has about 150 million refrigerators, 190 million washing machines, 400 million televisions and 26 million computers. Focussing on refrigerators; the production of refrigerators and freezers in China increases annually by 16%. There are more than 20 brands and 30 production lines in domestic refrigerator trade. Most house hold appliances came into use in the mid-1980’s and overrun operating life (10-15 years). Only 1/10 of the total house hold appliances were recycled by legal recycling corporations. All these products have become a mountain of junk in the last few years and are at its peak. Also, what is adding to the mountain are illegal imports from mainly the USA, Korea and Japan. Statistical predictions show that the number of end-of-life e-waste will keep increasing rapidly until the year 2015, at least[4]. E.g. 5 million computers, 5 million televisions and 4 million refrigerators will become obsolete this year only.

In addition to the fact that the amount which is recycled is very minimal, recycling is mainly done by manual dismantling. Small and back-yard workshops use methods such as acid baths to retrieve gold, open burning and unprotected removal of hazardous components. E-waste is stripped of valuable components and residues and large amounts of materials are dumped in landfills, fields, rivers and irrigation ditches. There are hardly any provisions to store or treat the hazardous materials which are compounds of all these products. These are highly toxic and especially harmful to human health and environment if not dismantled or disposed of carefully. Most electronic waste is shredded without proper disassembly, and hazardous substances are dispersed into the recovered metals and shredded waste. Furthermore, toxic substances (in the form of gasses) escape into the environment, are burnt as alternative fuel or leak into the ground after disposal by landfilling. Last but not least, the work in many (illegal) recycling workshops is carried out by poorly paid migrant workers and sometimes children, who work under inferior conditions and face severe health problems.

In addition to the fact that the amount which is recycled is very minimal, recycling is mainly done by manual dismantling. Small and back-yard workshops use methods such as acid baths to retrieve gold, open burning and unprotected removal of hazardous components. E-waste is stripped of valuable components and residues and large amounts of materials are dumped in landfills, fields, rivers and irrigation ditches. There are hardly any provisions to store or treat the hazardous materials which are compounds of all these products. These are highly toxic and especially harmful to human health and environment if not dismantled or disposed of carefully. Most electronic waste is shredded without proper disassembly, and hazardous substances are dispersed into the recovered metals and shredded waste. Furthermore, toxic substances (in the form of gasses) escape into the environment, are burnt as alternative fuel or leak into the ground after disposal by landfilling. Last but not least, the work in many (illegal) recycling workshops is carried out by poorly paid migrant workers and sometimes children, who work under inferior conditions and face severe health problems.

CFC’s and the Pilot Project

Following agreements amongst other counties laid down in the Protocol Protection of the Ozone Layer[5], China government has promised to stop using CFC materials in the production of refrigerators by 2007, but this does not solve the current problem of millions of tonnes of discarded refrigerators. Currently CFC’s are still released into the atmosphere. CFC’s in refrigerators are found in compressors and in insulation foam. In order to recover, store and neutralize CFC’s, specialized equipment and procedures need to be followed. Furthermore, the compressors also contain oil which is not collected and mostly seeps into the ground. Proper recovery is also needed here.

This Pilot Project will concentrate on recycling of refrigerators. RPCR will set up a professional recycling plant which will properly dismantle refrigerators, recover CFC’s and treat, store and neutralize other harmful substances released in the process. RPCR will set up a collection system in cooperation with local governments. As refrigerators (along with all other e- waste) are mainly collected door-to-door by individuals without business licenses or a fixed collection place, and consumers expect to be paid by the collectors for their discarded appliances, it is crucial to involve local governments. It is very important that they support this initiative by issuing and enforcing local legislation regarding disposal of this waste. The local Environmental Protection Bureau of Tanshan will require examination of this project for approval (Yutian County falls under the Tanshan area). The Yutian Investment Promotion Bureau has reacted positively to this initiative and would welcome and support this project as it is fits in their policy of environmental protection. A letter of support is added in Annex 8.

RPCR will start, on the smallest scale possible, with the dismantling and recycling of 195.000 refrigerators during the Pilot Phase. -(Note that this will keep 70 tonnes CFC’s from escaping into the atmosphere and 50 tonnes of oil seeping into the ground)- Turnover will be € 950.521 for the Pilot phase. The Project will be able to recycle 30% more material on refrigerators, which pushes the percentage of re-usable materials up to 90%. RPCR will set up a collection system with support of local governments in order to achieve a national network in Hebei province for the coming years. RPCR will grow to 468.000-500.000 refrigerators by year 5.

Author: Patrizia Sterenberg

-Chinese woman smelts computer circuit boards over an open stove to extract metals. The fan is an attempt to disperse the highly toxic fumes created by the smelting. "Copyright Stichting Greenpeace Council"-

[1] Summary of new Waste Electronic and Electrical Equipment (WEEE) Directive. See Annex 10.

[2] “The recycling and disposal of electrical and electronic waste in China-legislative and market responses.” C. Hicks, R.Dietman, M.Eugster.

[3] “Electrical and electronic waste management in China: progress and the barriers to overcome.” X. Liu, M. Tanaka, Y.Matsiu, Okayama University, Japan.

[4] “Status quo of e-waste management in mainland China.” J. Li, B. Tian, T. Liu, H. Liu, X. Wen, S. Honda; Department of Environmentsl science and

Engineering, Tsinghua University, Beijing.

[5] Vienna Convention for the Protection of the Ozone Layer, 1999 Montreal Protocol.

Subsidy: 250.000 Euros

ICT stands for Information and Communication Technology and involves a very wide range of products and services. Web development is one of the services provided within the ICT sector. Web development is a broad term that incorporates all areas of developing a web site for the World Wide Web. This can include graphical web design, actual coding of pages, backend programming, and web server configuration. Due to the large role of the internet in today’s live, marketing and communication concepts increasingly make use of the internet. This means that ICT and Marketing and Communication now work together to deliver richer experiences to the audience by creating highly interactive theme sites and games (e.g. www.koffieleut.nl, www.lipton.nl).

Concepts of these campaigns are developed by Marketing, Communication and Strategy agencies; the actual development is done by development studios specialized in web development and web design. For larger businesses and organizations, web development teams can consist of hundreds of people, while smaller organizations may only require a single webmaster.

The growth of this industry is being pushed by businesses wishing to sell products and services to their customers and to automate business workflow. Although web development is only one aspect of ICT, it has become a crucial part in almost every business process and communication to clients (both business and consumer). In order to grow to a modern economy, remain competitive and gain larger market access, companies need to invest in web development. In our modern economy  today, increasing investments in this area are being made.

today, increasing investments in this area are being made.

So far, in Suriname, ICT is an underdeveloped sector. This sector has not moved forward in the last 20 years. Existing companies in this sector have come to a standstill as relative high investments in hardware and training of staff cannot be made profitable on the local market, Suriname. This market on its own is too small to justify any investments. Therefore, export to the regional market (Caribbean) and Europe is the only way to update and expand this sector in Suriname.

The aim of NV Spang Makandra, a joint venture between Us Media Holding BV and Cybermango NV, is to become a technologically and creatively innovating full service e-media development studio. Spang Makandra will demonstrate commercial viability of a Suriname based e-media and software development studio. It will update the current level of knowledge to international standards through Us Media’s expertise and subsequently sell its products on the local market through the already existing business base of Cybermango. In principle, Us Media in The Netherlands will source assignments from Dutch and European clientele for Spang Makandra. After the pilot project, both Spang Makandra as well as Us Media will source assignments in Europe.

Het laatste nieuws (april 2009) Spang Makandra: http://www.usmedia.nl/nieuws/ict_opleiding_suriname_voorbereidingen_in_volle_gang

http://www.usmedia.nl/nieuws/koesikwarano_studenten_worden_leraren

Article 2008:

Spang Makandra has finalized the extensive training modules with 18 trainees and is well under way.

For more information and news on how Spang Makandra is doing look at their website: www.spangmakandra.com

PRI collection site.

Mrs. Sterenberg Salinas, regularly working in Kampala, encountered the obvious problem of bottles littered in the streets of Kampala and saw an opportunity for a PSOM project by recycling and adding value to waste. Mr. Somani of Rwenzori also had a desire since many years to, as a producer of plastics, take corporate responsibility and contribute to the solution of discarded waste. Both Mrs. Sterenberg Salinas and Mr. Somani joined hands and found a partner in Plastic Herverwerking Brabant from The Netherlands.

Since September 2004 both PHB and Rwenzori have been discussing how best to develop plastic recycling activities together in Uganda. The discussion also embraced the approach of developing an appropriate collection system. Both partners saw a viable opportunity for the recycling of plastic post consumer waste in Uganda.

A PSOM proposal was submitted to the EVD in The Hague in August 2005 and was rewarded a PSOM subsidy in December 2005.

Plastic Recycling Industries (Uganda) Ltd would was legally formed beginning of 2006.

2016: PRI Ltd. was purchased by SAB MILLER around two years ago. PRI is still running and they have installed a new water treatment system and are producing 3.000 MT a month approx.

Abstract (August 2005 PSOM proposal)

PET bottles are used for e.g. mineral water, juices and cooking oil. HDPE is used for the production of crates, buckets, jerry cans, shampoo and cosmetic packaging, and LDPE for industrial sheet, film and plastic carrier bags. After consumption plastic waste is discarded, it ends up on household garbage heaps, at the Kiteezi landfill, alongside roads, on agricultural land, or is burned (“back-yard” fires). This not only result in visual pollution, the air pollution as a result of burning plastics is tremendous. As main producer of bottled mineral water, packed in PET bottles, Rwenzori Beverage Ltd. feels that it should take corporate responsibility and reduce the negative impact on the environment by recycling plastic waste.

So far, post consumer plastic recycling has been restricted to one or two small scale semi-commercial enterprises in Uganda and no large scale recycling activities have been attempted. This is because there is no organised and efficient collection system in place and its development requires great effort, funding, organisational capacity and risks. Obviously, the input of sufficient waste material is crucial for the operation of a recycling process.

PRI, starting as a Pilot Project will demonstrate the commercial viability of post consumer plastic waste recycling in Uganda. The purpose of the project is to establish a pilot industrial post consumer plastic waste recycling process. The input material is collected and pre-sorted PET bottles and (HD)PE products. The end product consists of washed and dried flakes. PRI will export these flakes to international markets (e.g. India, China, Pakistan, and Indonesia), regional markets (e.g. Kenya, South Africa) as well as sell its end product on the local market. Flakes can be brought back into the production process with virgin material. 10 to 50% recycled flakes can be mixed in without reducing the quality of the end product.

The capacity will be a washing recycling installation of app. 650kg/hr input. The aim is to process 500 tonnes (t) of PET and 500t of PE in the second year. The third year PRI wishes to produce 1.100t PE and 1.400t PET flakes (the ratio of processed PET/PE might change when more PET and less PE is collected). PRI will employ a total of 30 people during the pilot project.

Final Report PRI 2008:

Plastic Recycling Industries Ltd. (PRI) has finalised the last result on the 29th of February 2008. That day it produced 651 tonnes of recycled post consumer plastic waste.

PRI now employs 30 persons. Also 40-60 woman work on temporary contracts. The indirect employment is considerable and is estimated to be 800 persons.

Both directors, Mr. Driessen and Mr. Somani, were present and signed the Protocol of Production with great pride.

Since its start PRI has gained much respect and reputation in Kampala. Many Governmental and non-governmental organisations have visited PRI.

CNN made a short news item for CNN World report, several Ugandan ministers have visited, Bill Gates Foundation came by, UNIDO paid a visit in February 2008 and BUDS (Private Sector Foundation Uganda) has offered to assist in financing new machinery for the spin off.

Most hotels in Kampala collect their plastic bottles for PRI to pick them up. Hospitals collect all their plastic waste and their drip bottles and many organisations are collecting for themselves for sale to PRI.

PRI has established itself in the market, is know throughout Kampala and exports successfully to China.

One major positive effect is that HDPE (jerry cans, yogurt containers etc.) is mostly sold and consequently re-used locally. Many companies producing HDPE products send their factory waste to PRI to be recycled so that they can mix it back into new production.

They now have to import much less virgin material into Uganda, saving on costs, transport and indirectly on environment impact.

Another very positive effect is the creation of direct but mostly indirect employment on a relatively large scale. PRI estimates that at least 600 persons have gained a new living through collection and sales of post consumer waste.

Many women have made it their job to collect plastic waste and deliver to PRI on a daily basis.

|

The lady that just delivered her collected waste (HDPE containers) has her waste weighed on the PRI scale by a PRI employee. Her name and today’s delivery is registered. She is paid directly at the PRI payment office.

PRI production area. Packed bags are stored until the next container leaves for export.

HDPE recycled flakes from water bottle caps (bottle is PET) is separated by the equipment (sink float system) and stored and sold separately. Two-coloured HDPE yogurt containers are run into the recycling line and gives a high quality HDPE flake as it has no other colours mixed in.

At the end of the recycling line, the PET flakes are collected in larger big bags for export.

Behind the PRI factory building: storage waste waiting for first pre-wash and granulation to remove the most of dirt before being fed into the recycling line.

PRI ordered a custom made (in Uganda) washing machine to pre-wash the dirtiest bottles and remove most dirt and sand particles before feeding the material into the recycling line.

A Chinese granulator/shredder has been purchased to pre-granulate the dirties of bottles.

Many bottles have so much dirt that they ware out the knives of the recycling line too quickly. Waste material in Uganda is much dirtier then can be found in Europe.

The knives of the main granulator (from The Netherlands) in the recycling line are very costly to purchase and sharpen.

This made the partners decide to purchase a cheaper, lower quality granulator from China with cheaper knives to pre-granulate the dirty material. This dirty material is then washed in above mentioned pre-washing machine to wash off the dirt.

This pre-step gives the end product the highest possible quality.

Dirty plastic waste

Dirty and clean material.

PRI offices, kitchen, and workshop/meeting room: downstairs; changing rooms and toilets for staff upstairs, first floor.

PRI offices, kitchen, and workshop/meeting room: downstairs; changing rooms and toilets for staff upstairs, first floor.

PRI office for cash payment of collectors after having weighed their brought in materials. PRI car.

PRI office for cash payment of collectors after having weighed their brought in materials. PRI car.

Clean bottles from hotels just brought in, ladies are checking whether there is no contamination or other bottles mixed in. Then ready for processing.

UNIDO visit at PRI office by coincidence Mr. Driessen was also in Uganda. Left corner, Mr. Somani (Rwenzori partner), right corner, Mr. Byarugaba (Manager PRI). Picture made by Mr. Driessen. Middle, P. Sterenberg

A secondary development PRI would like to mention here is that since this project has started to be known throughout the country and more and more Ugandans have learned that money can be made from taking plastic bottles from their environment, the practice of burning of plastic bottles has become much less.

Since day and age, coming from the airport in Entebbe into Kampala area, the air would smell of burned plastics. Many people feel this typical smell has changed and reduced considerably and noticeably. Plastic bags are still burned by Ugandan households but the strong smell of burning PET and PVC bottles has very much been reduced.

Although we cannot prove it, we think that this very positive effect is due to the development of PRI’s activities.

Latest pictures: JUNE 2010, courtesy of Joost Bolt from the EVD.

New logo:

Alex Buyarugaba (left) with new manager:

Still lots of plastics coming in………….